When it comes to manufacturing processes, machining and fabrication are two terms that are often used interchangeably, but they represent very different methods of shaping and assembling materials. While both are essential to modern manufacturing, understanding their key differences can help you choose the right approach for your project.

What is Machining?

Machining is a subtractive manufacturing process that involves removing material from a solid block or workpiece to create a desired shape or part. Using tools such as lathes, mills, or CNC machines, the material is cut, drilled, or shaped to precise specifications. Machining is often used for creating parts with complex geometries, tight tolerances, and high-quality finishes.

Key Features of Machining:

- Subtractive process: Material is removed from the workpiece.

- High precision: Ideal for parts that require tight tolerances and smooth surfaces.

- Materials: Can be used with metals, plastics, and composites.

- Common applications: Aerospace, automotive, and medical industries where precision is critical.

What is Fabrication?

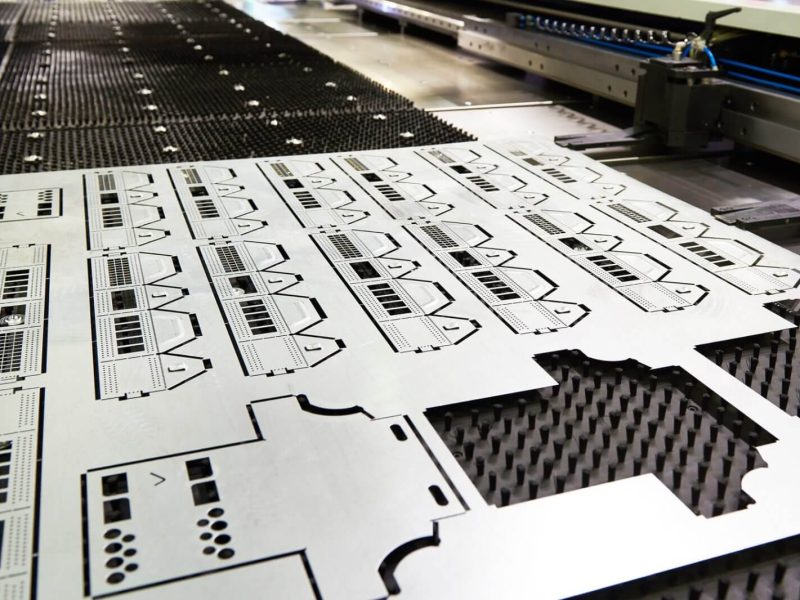

Fabrication, on the other hand, is an additive or assembly-based process that involves building parts by combining or shaping materials through various techniques like welding, bending, cutting, or assembling. Fabrication is commonly used to create larger structures or parts where complex assembly or welding is required. It’s a more versatile process for making frames, large structural components, and items that don’t require the extreme precision of machining.

Key Features of Fabrication:

- Additive process: Materials are joined or shaped, often without removing excess material.

- Versatile: Ideal for larger structures, frames, or bulkier components.

- Materials: Typically involves metal, steel, and sometimes wood or plastic.

- Common applications: Construction, shipbuilding, heavy machinery, and structural components.

Key Differences Between Machining and Fabrication

- Process Type

Machining is a subtractive process (removes material), while fabrication is an additive process (materials are joined or shaped). - Precision vs. Volume

Machining excels at producing high-precision, complex parts with tight tolerances. Fabrication is often used for creating larger, bulkier components or structures where precision may not be as critical. - Materials Used

Both machining and fabrication can work with a variety of materials, but fabrication is more commonly associated with thicker metals like steel, while machining can handle a broader range of materials, including softer metals and plastics. - End Products

Machining is used for parts like gears, shafts, and intricate components, whereas fabrication is more suitable for larger products like frames, tanks, or piping systems.

Both machining and fabrication are vital manufacturing techniques, but understanding the differences between them can help you select the right method based on your project’s needs. Machining is best for high-precision, detailed parts, while fabrication excels at producing larger, structural components. By knowing when to use each, you can optimize your manufacturing process and ensure that your parts are made to the highest standards.